Georgia Refinery Wastewater Improvements

- Food + Beverage

- Private Sector

Market

- Engineering

- Industrial Water

- Water

Services

- Dawson, Georgia

Locations

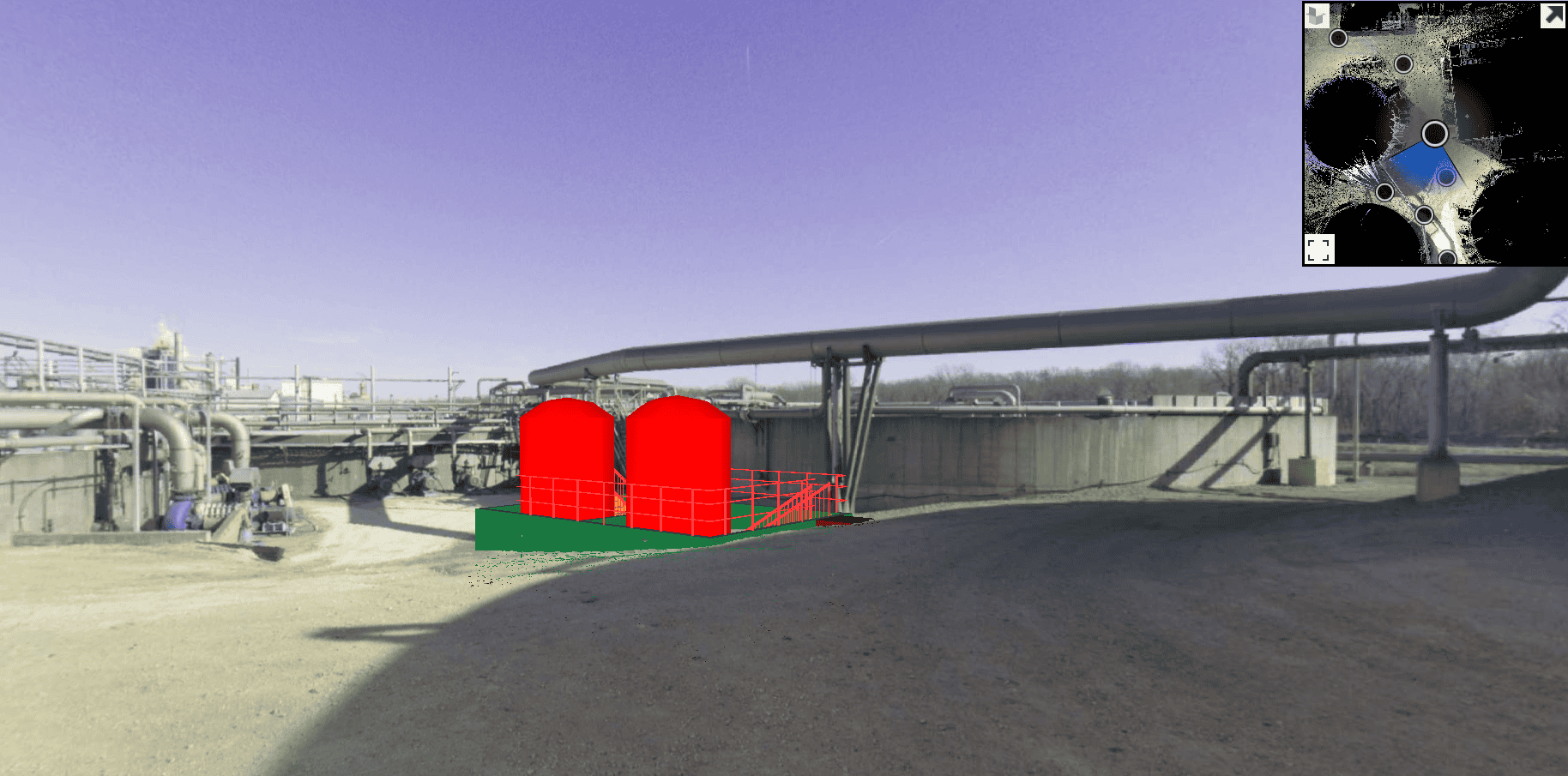

Challenge: The private industrial facility in Dawson, Georgia, has an extraction and refinery processing facility that separately produces and processes wastewater prior to independently discharging it to the local municipality. Since 2021, the refinery wastewater system has intermittently exceeded the local limits for Fats, Oil, and Grease (FOG) and Total Suspended Solids (TSS).

High loadings were coming from multiple sources – the refinery tank farm containment area which had high FOG/TSS concentrations and high flows during periods of heavy storm activity, railcar wash water, upset events from the refinery production area that introduced both higher flows, and FOG/TSS levels without warning to the wastewater operation, and lack of sensitivity of online turbidimeters to detect FOG/TSS levels that may exceed the local limit even though the wastewater treatment system appears to be performing well. FOG was the primary compliance issue. The stormwater was also being sent through their existing Dissolved Air Flotation (DAF), which increased the hydraulic loading on the DAF.

The private client selected HR Green to complete an options analysis and Front-End Loading (FEL) level 2 conceptual design for FOG/TSS removal improvements. The project goals were to reduce FOG exceedances, improve pH control, improve automation and controls, and improve hydraulic equalization.

Solution: The HR Green team conducted a site visit to observe the conditions at the plant. This was followed by an alternatives analysis. Alternatives included:

- Housekeeping improvements for source reduction of FOG.

- Re-routing of cooling tower and boiler blowdown streams around the existing DAF to reduce peak flow and hydraulic loading.

- Installation of a new DAF parallel to the existing DAF to provide increased treatment capacity.

- A new Oil-water separator (OWS) was recommended for high FOG streams such as the railcar wash tank.

- In addition to the new DAF and OWS, a new Equalization (EQ) tank was recommended to provide additional hydraulic equalization of the process water along with a new lift station to send the flows to the EQ tank.

- An alternative to the EQ tank and DAF was to construct a 2-cell retention pond to provide greater hydraulic equalization and contain the flows from tank farm containment area with high FOG and TSS concentrations. A mechanical OWS was recommended to remove FOG from cell 1 of the retention pond while slowly pumping the flow to their existing wastewater system.

Benefit: The private client selected the EQ and new DAF to reduce peak flow and loading, and to increase treatment capacity for improved permit compliance.